Dutcher Lab Research Overview

Research Projects

We have two major research projects that involve:

- a novel sustainable nanoparticle called phytoglycogen, and

- the application of machine learning techniques to analyzing infrared microscopy measurements of cross-linked polyethylene pipe.

In addition, we have an active collaboration on the production and characterization of plant-based “meats” with a texture that approximates that of a fibrous meat-like steak, as well as collaborations to use atomic force microscopy to study biological cells and hydrogels.

Phytoglycogen Nanoparticles

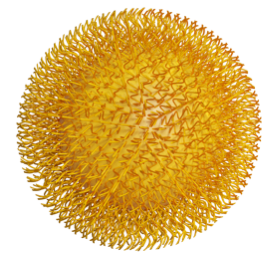

We study a novel polysaccharide called phytoglycogen that is produced as dense, compact nanoparticles in the kernels of sweet corn. The natural polymer particles have a special dendritic or tree-like architecture that imparts special properties. Because of their unique physical properties as well as their biocompatibility, non-toxicity and digestibility, the particles have distinct advantages for use in applications involving the human body, such as personal care, nutrition, and biomedicine.

To study the properties of these nanoparticles, we use a wide range of experimental techniques that includes small angle neutron scattering (SANS), atomic force microscopy (AFM), infrared (IR) spectroscopy, ellipsometry, rheology, dynamic light scattering (DLS), and size exclusion chromatography-multiangle light scattering (SEC-MALS). The results of our measurements of the structure, morphology, hydration, and mechanical properties have shown that native phytoglycogen nanoparticles are soft, hairy, porous, and hydrated. We also use computational techniques such as dynamic self-consistent field theory to model native and modified phytoglycogen nanoparticles and their interaction with other small molecules.

Important things that we have learned:

- Phytoglycogen nanoparticles are compact with a uniform density throughout the interior of the particles.

- Phytoglycogen nanoparticles are “hairy”: they have short chains that extend from the outer surface of the particles.

- Hydration water within phytoglycogen nanoparticles is well ordered and has slower dynamics than bulk water.

- Swelling of films of phytoglycogen nanoparticles is consistent with hydration forces acting between chains within the particles.

- Increasing the concentration of phytoglycogen nanoparticles in water produces a colloidal glass transition.

- Pressing on individual nanoparticles with an AFM tip shows that hydrated particles are soft and easily deformed.

- There is an intimate link between the amount of hydration water within the particles and their bulk modulus and Young’s modulus.

We can also modify phytoglycogen nanoparticles in several useful ways:

- We can reduce the size and stiffness of the particles through partial digestion (hydrolysis either with acids or enzymes) and by using high shear extrusion. Acid hydrolysis of the particles produces decreases in the size and stiffness of the particles. Acid hydrolysis of the particles produces a qualitative change in their colloidal glass transition as the particles are forced into contact in high concentration dispersions. High shear extrusion of the particles produces a decrease in size and also changes the density and stiffness of the particles.

- We can add charged groups to the particles. Adding a positive charge to the particles can produce an increase in the stiffness of the particles.

- We can add hydrophobic groups to change their interaction with water. High levels of modification with a charged, hydrophobic compound (octenyl succinic anhydride) result in the formation of hydrophobic “seeds” on the outer surface of the particles described by the raspberry model.

- We can associate bioactive compounds with the particles for bioactive and drug delivery applications.

In our current research, we are investigating new ways to modify phytoglycogen nanoparticles to produce novel properties and identify new applications, and we are developing computer simulations of phytoglycogen nanoparticles using the technique of dynamic self-consistent field theory. This work involves collaborations with Prof. Rob Wickham (Guelph), Prof. Jon Nickels (Cincinnati), Dr. John Katsaras (Oak Ridge National Laboratory) and Prof. Mario Martinez (Aarhus).

This safe, natural nanotechnology is being commercialized by our spinoff company, Mirexus Biotechnologies, which is working with customers to develop innovative products for personal care applications.

Machine Learning Approaches to Analyzing Infrared Microscopy Measurements of Cross-Linked Polyethylene Pipes

Machine learning is revolutionizing the analysis of large databases. We are contributing to this revolution through our application of deep learning to the analysis of infrared spectra.

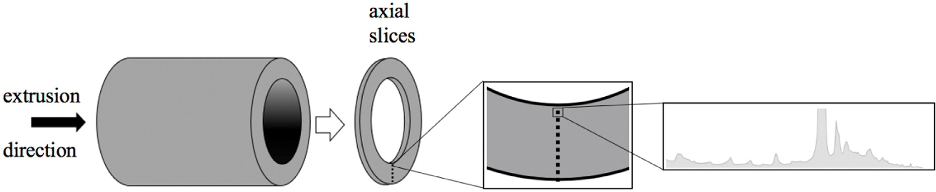

We are studying cross-linked polyethylene (PEX-a) pipe, which you likely have as the water lines in your house. Commercial pipe formulations include additives that offer enhanced protection against degradation processes such as oxidation and UV-degradation. We use infrared (IR) microscopy to measure local changes to the polyethylene and the additives with in-service use at elevated temperature and pressure.

We place the pipes in an in-house water recirculation system that allows us to produce accelerated ageing of the pipes at different temperatures and environmental conditions. Aggressive ageing of the pipes can produce cracks in the pipes that ultimately leads to pipe failure. Our work is focused on understanding the formation and growth of cracks so that the lifetime of PEX-a pipe can be extended.

Important things that we have learned:

- We have used a deep learning approach based on a beta-variational autoencoder to identify the underlying physicochemical changes associated with ageing of PEX-a pipe, including the characteristic signature of cracks that formed at the inner surface of pipes.

- We used principal component analysis of infrared microscopy data to quantify the hydrolysis of stabilizing additives with ageing of PEX-a pipes.

- We used principal component analysis of infrared spectroscopy data to classify different formulations of PEX-a pipe.

Other Projects

We are collaborating with Prof. Mario Martinez of Aarhus University in Denmark to produce and characterize plant-based meat analogs.

- We have created plant-based, fibrous, high moisture meat analogs using hemp seed proteins.

We are also collaborating with several biology groups at the University of Guelph to use atomic force microscopy to study biological cells and hydrogels.

- We have measured the stiffness of polyacrylamide hydrogels and their ability to adhere osteosarcoma cells.

Industry

The Dutcher lab has several exciting collaborations with companies who are interested in understanding the properties of polymers and biopolymers for use in different applications.

Funding Sources

We have funding from a variety of sources, including the Discovery Grant and Collaborative Research and Development programs of the Natural Sciences and Engineering Research Council of Canada, the Canada Foundation for Innovation, the Ontario Research Fund, the HeatLink Group, and Mirexus Biotechnologies.

In the past, we have received funding from the Canada Research Chairs program, the Engage program of the Natural Sciences and Engineering Research Council of Canada, the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), the Advanced Foods and Materials Network, the Ontario Centres of Excellence, Iogen Corporation, 3M Canada, Dow Chemical, Materials and Manufacturing Ontario, the Premier’s Research Excellence Award program, and the Ontario Innovation Trust.